Purchasing

Procurement Department

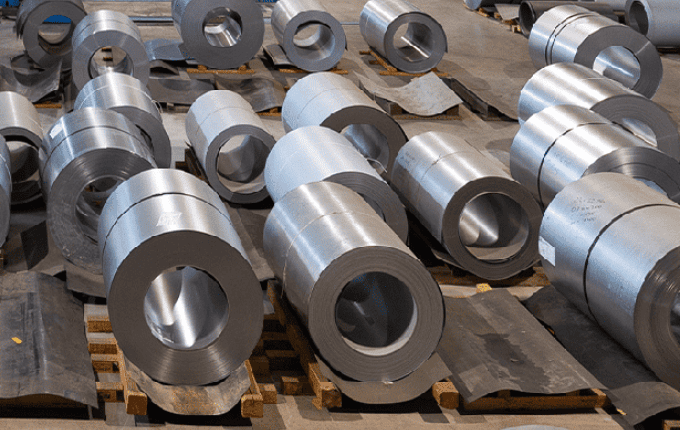

At Jyoti Pipes, procurement is a cornerstone of our operational excellence. We source only the finest stainless steel materials from globally recognized suppliers to ensure unmatched quality, precision, and consistency in every product we manufacture. Our procurement strategy focuses on building sustainable, long-term relationships that align with our commitment to innovation, cost efficiency, and reliability.

Suppliers

We collaborate with trusted and certified suppliers who share our vision for excellence and ethical business practices. Every partnership is built on transparency, integrity, and continuous improvement. By working closely with industry leaders, our procurement team ensures a stable supply chain, optimized costs, and materials that meet international standards of performance and sustainability.

Our Steel Supply Chain Partners

Jindal Stainless Steel (JSL) — India’s largest stainless steel producer

Outokumpu — Finland-based global leader in high-performance stainless steel

POSCO India — Renowned for ultrapure stainless steel coil and sheet supply