Precision Production

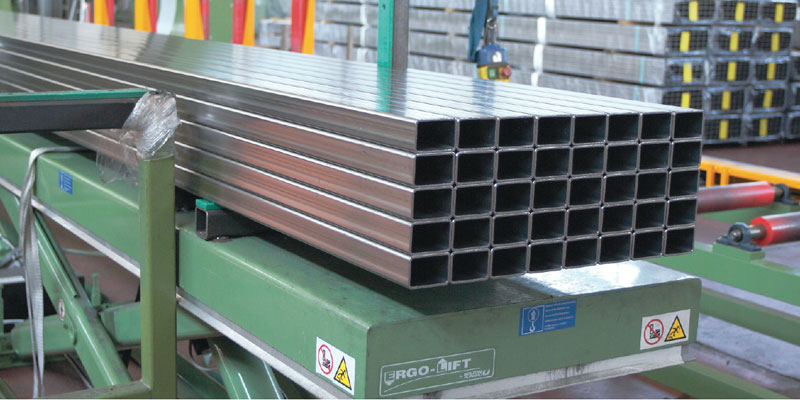

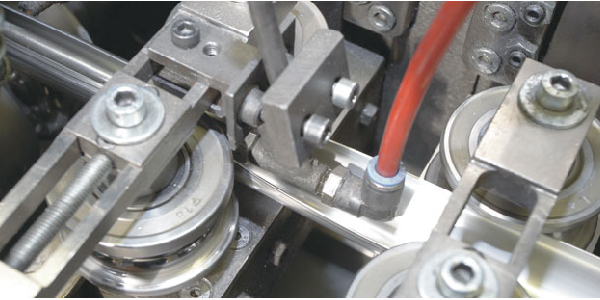

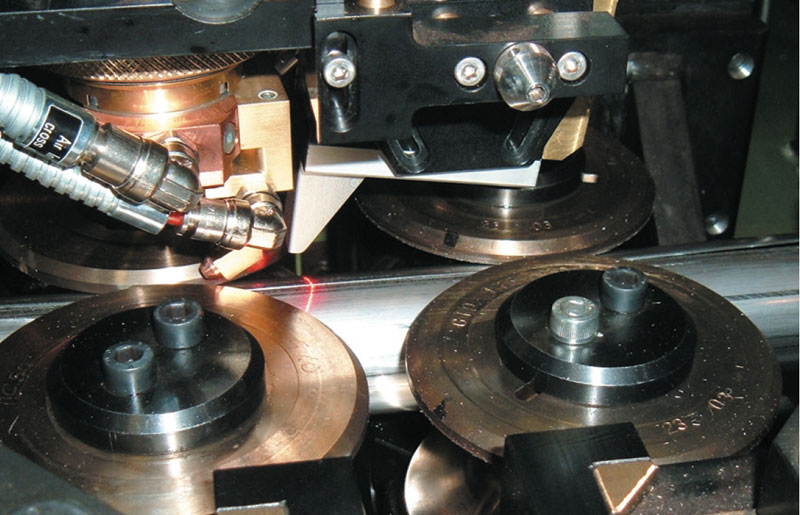

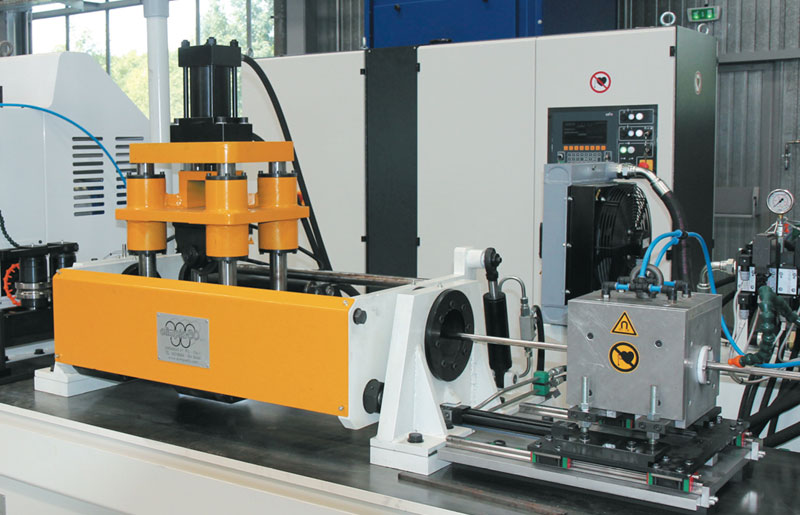

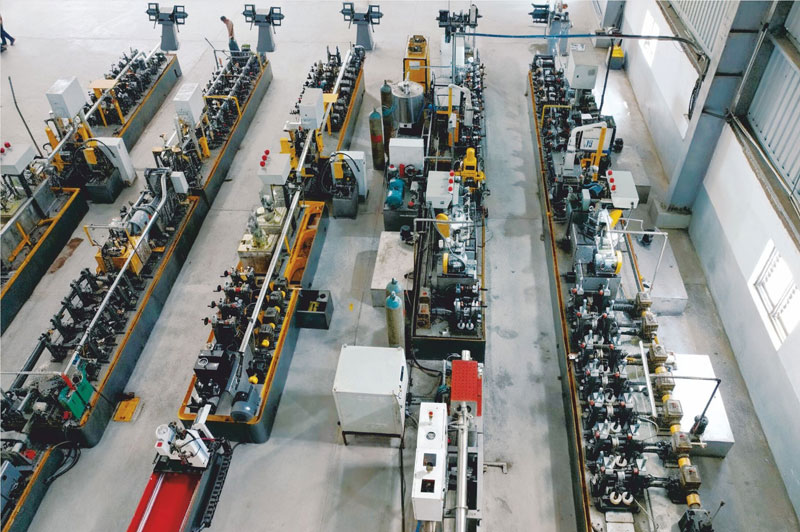

Already part of the Group and a global leader in stainless steel production and finishing lines, JYOTI-INOX operates with state-of-the-art laser welding systems, in-line heat treatment furnaces, and advanced weld rolling tools for precision, efficiency, and unmatched product quality assurance.

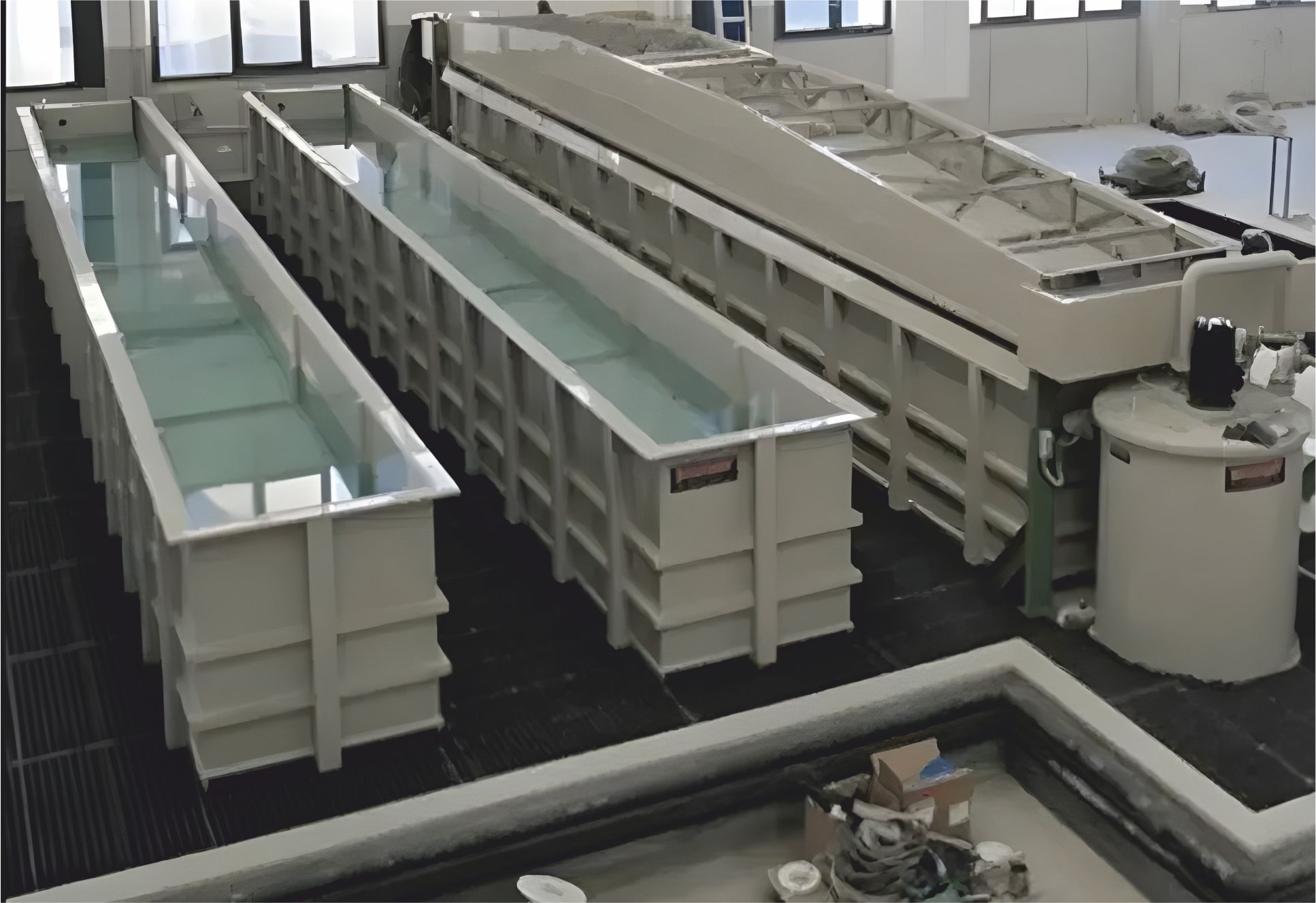

Our technical oce develops tailored solutions for special pipes, while surface finishing is highly expert, reliable, and precise to ensure superior durability and consistent quality output, meeting the highest industry standards and client expectations.