QUALITY TESTING

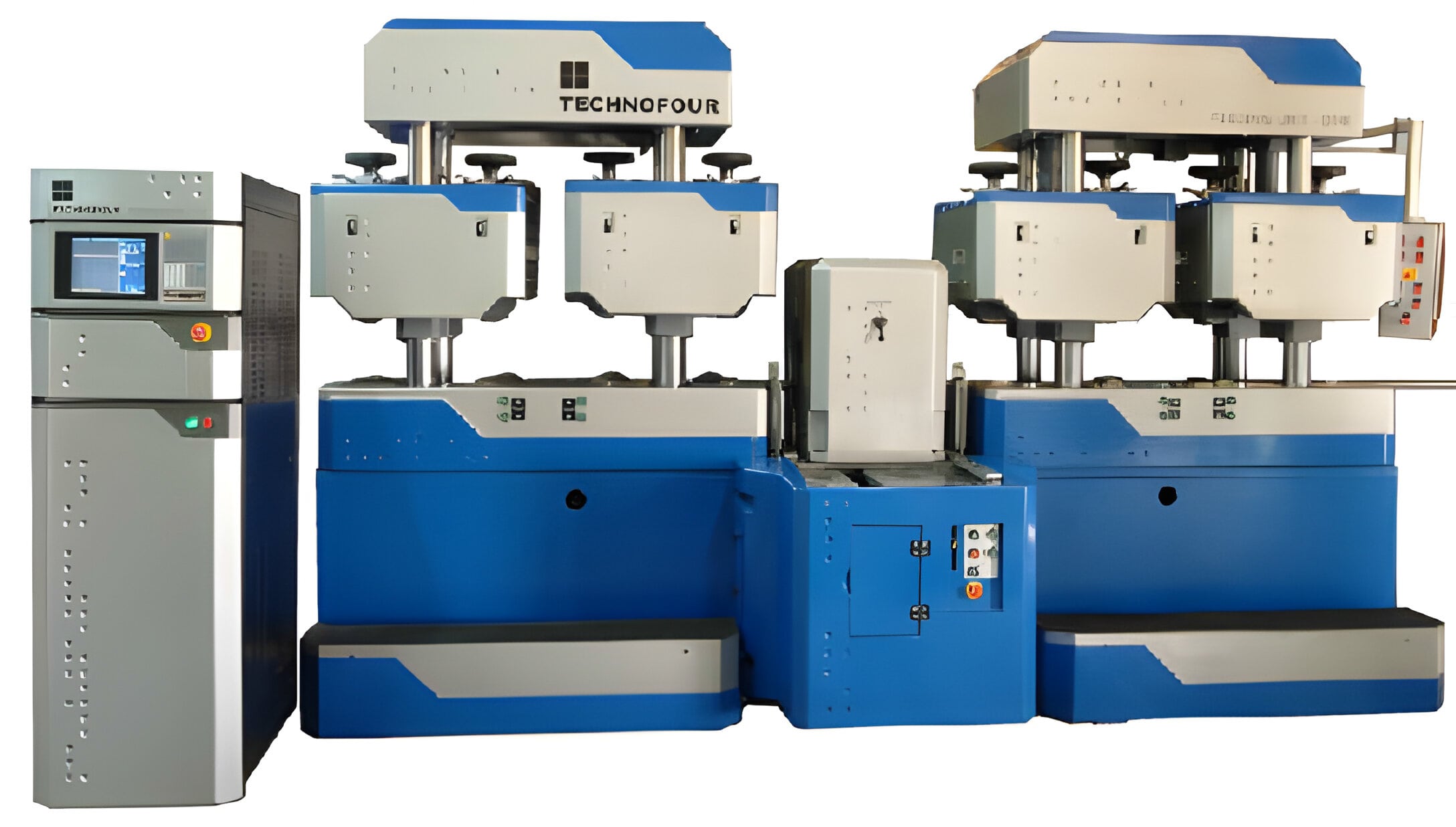

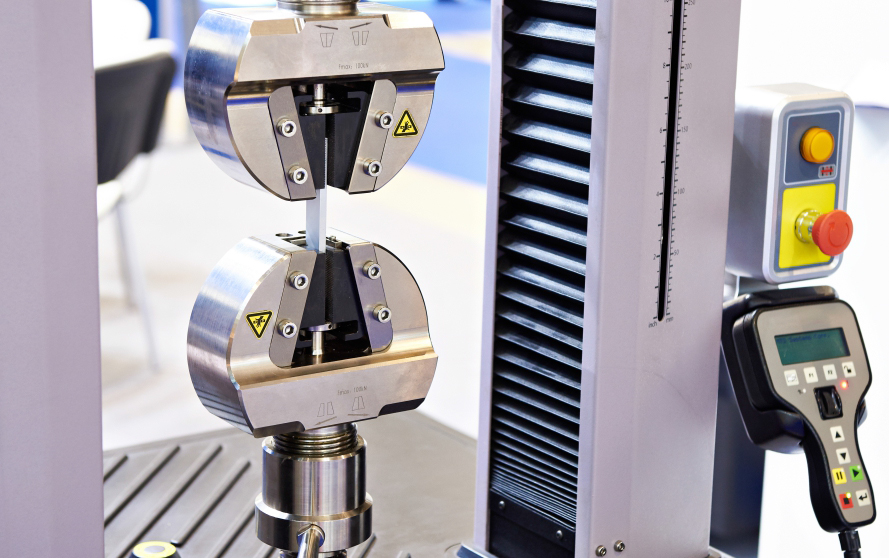

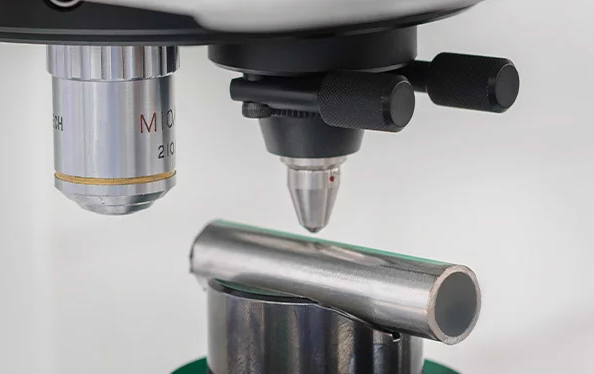

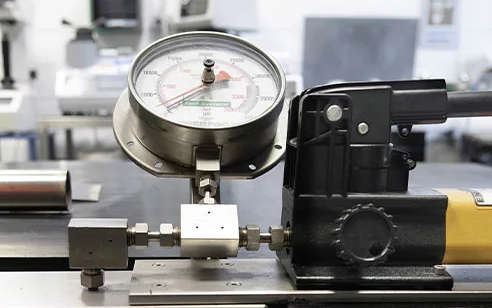

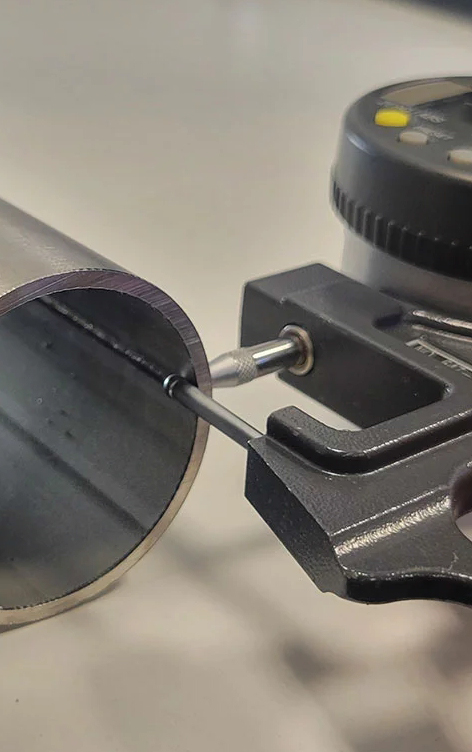

Jyoti pipes’s strong point is the quality of the products we supply to our customers. From the very first days of the company, it has always paid the utmost attention to the quality system and quality department. With two in-house laboratories, fully equipped for both destructive and non-destructive testing, Jyoti pipes is in a position to immediately assess the quality of its production and to investigate any arising conditions of the material.

Following the most stringent requirements from standards that govern the production of our welded tubes, the company prides itself on manufacturing high-quality products for the most demanding markets.

Duly certified as per:

- ISO 14001:2004 - Certification for environmental management.

- REACH (2007) - Full compliance with the European Chemicals Regulation

- ISO 9001:2015 - Quality Management System certification.

- ISO 45001:2018 - Certification for occupational health and safety.

Jyoti pipes can guarantee complete suitability of the products to customers’ needs. All manufactured tubes are technologically tested according to a QCP linked to every production. A full array of destructive and non-destructive tests guarantees the quality of the tubes, and the two in-house, fully equipped laboratories allow for immediate results, assessing production quality from start to end.